Seamless CS to ASME SA214 High Finned Tube L Type

L Finned Tube(LL/KL Finned Tube)

Datang offers a range of wrapped finned tubes, including L-footed, double overlap (LL) fins, and knurled (KL) finned tubes.

- Tube Material:Stainless steel,Tube Diameter:15.88-50.80 mm,Wall Thickness:1.0-3.0 mm

- Fin Material:Aluminum,Fin Thickness:0.4-0.5 mm,Fin Pitch:2.1-6.0 mm,Fin Height:6.35-25.4 mm

L Finned Tube

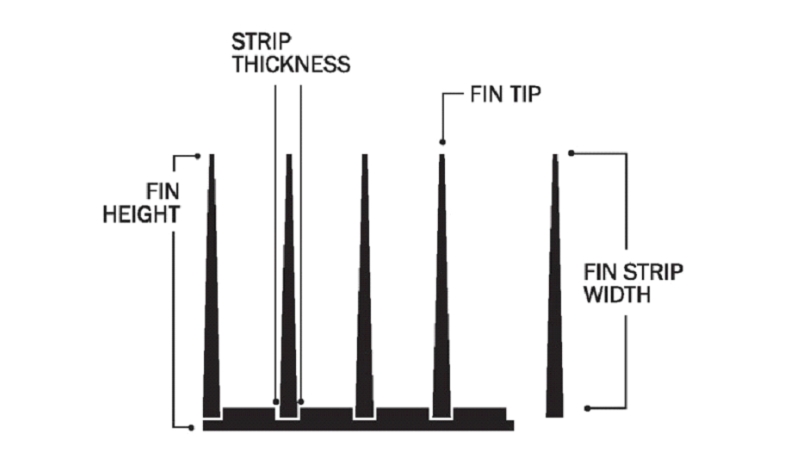

The L type finned tube features fins shaped in an L form, which are tension-wound onto the outer surface of the base tube. The “L” foot of the fin provides enhanced corrosion protection for the base tube.

LL Finned Tube

Similar to the L-type finned tube, the LL finned tube has overlapping fin feet that fully cover the outer surface of the base tube. This design offers superior corrosion protection compared to the standard L-type.

KL Finned Tube

The KL finned tube is manufactured similarly to the L-type but with an additional step: the base tube’s surface is knurled before the fins are applied. The fin foot is then pressed into the knurled surface, creating a stronger bond between the fins and the tube, which significantly enhances heat transfer efficiency.

- Datasheet

- Drawing

- Certificates

| Tube Material | Wall Thickness | Tube Diameter | Tube Length |

| All types | From 1.0 to 3.0 mm | 15.88 / 50.80 mm | Max. 18500 mm |

| 0.039 in to 0.118 in | 0.625 / 2 in | 728 in | |

| Fin Strip Material | Fin Strip Thickness | Fin Pitch | Production Capacity |

| Aluminum/Copper | From 0.4 to 0.5 mm | From 2.1 to 3.0 mm | 12000 m per day |

| From 0.015 to 0.019 in | From 8 to 11 fins/inch |

Seamless CS to ASME SA214 High Finned Tube L Type Appearance Dimension Inspection

Seamless CS to ASME SA214 high finned tube L type appearance dimension inspection is one of the important links to ensure the quality and performance of fin tubes.

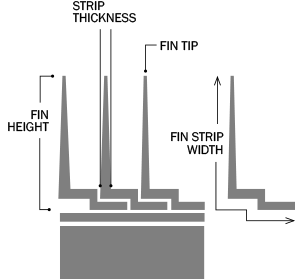

The inspection items mainly include fin height, fin spacing, fin thickness, base tube wall thickness and outer diameter, etc.

Datang Seamless CS to ASME SA214 high finned tube L type Bending Processing

Bending of fin tubes is an important step in the production process of Seamless CS to ASME SA214 high finned tube L types. Bending is to bend the Seamless CS to ASME SA214 high finned tube L type material through specific mechanical equipment to form a suitable curvature to meet different usage requirements.

This step requires strict control of the bending angle and curvature to ensure the fit between the fin and the base tube and the heat dissipation effect.

Seamless CS to ASME SA214 high finned tube L type Pull Off Test

Seamless CS to ASME SA214 high finned tube L type pull-off test is a test used to detect whether the fin tube will fall off when subjected to tension, mainly used to ensure the quality and reliability of the fin tube.

Datang’s this test is very important in the production process because the L fin tubes will be subjected to various stresses during operation, such as temperature changes and pipe expansion, which may cause the fin to fall off, thereby affecting the performance and safety of the heat exchanger .